- info@walcoom.com

- +86-318-5111380

Extruded Feed Spacers Enhance the Performance of RO Membrane Elements

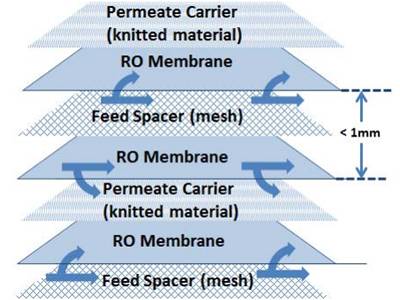

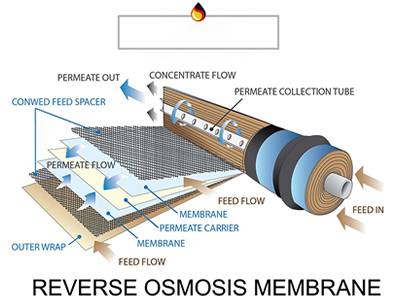

Flow channel feed spacers provide channels for the flow of the feed water. They are the essential parts of spiral-wound membrane (SWM) modules in reverse osmosis and nanofiltration. These mesh spacers act as an important role in determining the hydraulic conditions of the feed channel. The configuration and orientation of feed spacers affect the flux, pressure losses and fouling in the membrane process. This indirectly influences the unit cost of water production.

Feed mesh spacers are made of polypropylene through a single-step continuous extrusion process. The cross-section of feed spacers is thick which can endure the liquid impact. The middle part of the node is slightly thinner than the integral joints. Because of the extruding process, the shape looks like a slightly twisted. As an extruded plastic mesh manufacturer, we provide diamond netting and square netting for different feed water types.

Reverse osmosis feed spacer

Feed spacer geometry

Clear extruded feed spacer mesh

Filter scheme of spiral-wound membrane

Feature

- Twisted filaments for higher mass transfer.

- Achieve a balance between competing concerns.

- Bi-planar construction creates flow channels across the filter medium.

- Improve the flux without increase in pressure losses.

- Hydrophilic surface is resistant to the adhesion of bacteria & proteins.

- Various geometric configurations available.

Specification

- Material: polypropylene.

- Thickness: 14 – 38 mil.

- Hole Shape: diamond, square.

- Width: 30–55".

- Weight: 80–230 g/m2.

- Length: 500', 1000'.

- Package: packed into plastic bags, shipped by pallet.

| Picture | ||||||

|---|---|---|---|---|---|---|

| Item No. | 1406 | 1407 | 1908 | 1909 | 2110 | 3611 |

| Thickness (mil) | 14 | 14 | 19 | 19 | 21 | 36 |

| Tolerance (mil) | ±2 | ±2 | ±2 | ±2 | ±2 | ±2 |

| Hole Shape | Square | Square | Square | Square | Square | Square |

| Hole Size (inch) | 0.021 × 0.027 |

0.025 × 0.030 |

0.040 × 0.053 |

0.054 × 0.080 |

0.040 × 0.053 |

0.030 × 0.037 |

| Strand Per Inch | 25 | 27.6 × 25 | 17 × 14.6 | 15 × 11 | 16 | 16 × 13 |

| Width (inch) | 30.59/37.5 | 43.5 | 43.5 | 54.5 | 40 | 47.5 |

| Length (feet) | 500 | 500 | 500 | 500 | 500 | 500 |

Application

Feed spacers are professional used in spiral-wound membrane (SWM) modules in reverse osmosis and nanofiltration system.

The spiral wound membrane is made with feed spacer mesh

The section detail of spiral wound membrane

Schematic of spiral-wound membrane module

Feed spacer mesh are packed in roll

Inquiry for Our Product

Boegger Industech Limited

Email: info@walcoom.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.